By Frank L. Flood Asst. Engr., Metcalf & Eddy, Engineers, Boston, Mass.

Water Works and Sewerage. July, 1936. Vol. 83 No. 7 pg. 266

In the activated sludge process it is necessary to draw activated sludge from the final settling tanks. The major portion of the sludge so drawn is returned to the process and the remaining portion is removed for treatment and disposal. The practice with respect to rate of withdrawal of activated sludge varies. Some operators believe it advantageous to vary the rate of return sludge, to some degree, in accordance with the fluctuation of sewage flow or load of solids in the sewage. Others believe it advantageous to recondition the sludge by returning a larger proportion during the night when the detention period is longest and the sewage flow the weakest. In some cases it has been found necessary to increase the rate of withdrawal of activated sludge from the final settling tanks during the hours of peak rate of sewage flow. This, in order to prevent excessive accumulation of sludge in the tanks and the sweeping out of large quantities of suspended solids in the tank effluent.

In conjunction with such operations, and in the normal operation of any activated sludge plant, it is desirable to exercise a fairly close control over the rate of withdrawal and return of the activated sludge.

Several methods have been used to effect this control. One of the earliest schemes, as employed at the initial Milwaukee plant, was the use of swivel pipes. The pipes were attached to the outlet end of the activated sludge draw-off pipes and controlled by hand wheels. As the pipes were tilted, the hydraulic head on the sludge line was increased and the rate of flow thereby increased. This method of control is not entirely satisfactory in that it is sometimes difficult to govern the rate of withdrawal with accuracy. After adjustment in one position the rate of discharge may increase or decrease materially because of changes in the character of the sludge.

Another method of control consists of a telescoping pipe at the outlet end of the sludge withdrawal line. This operates on the same principle as the swiveled pipe and is subject to substantially the same objection. Several other methods of control such as by throttling valves, adjustable weirs, adjustable air lifts and variable capacity pumps direct-connected to individual tanks are also in use.

Adaptation of Venturi Rate Controllers

In an effort to overcome some of the difficulties experienced with the various methods of control of the rate of withdrawal of activated sludge, rate controllers of the Venturi type have been installed at the enlarged North Toronto, Ontario, plant. At this plant there are five final. settling tanks, each 65 ft. square at the top with circular bottoms. The withdrawal of sludge at the center is facilitated by sludge removal mechanisms of the revolving spiral blade type.

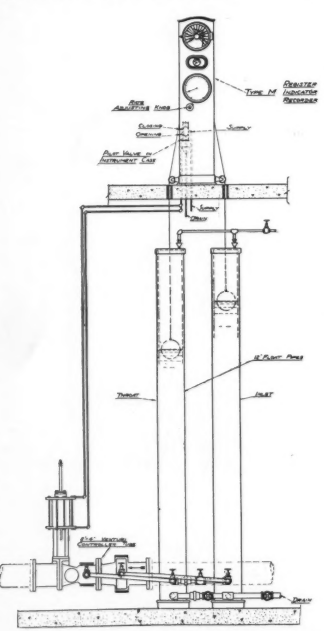

A 12-inch sludge withdrawal pipe extends from. beneath the center of the bottom of each tank to an operating gallery adjacent to the settling tanks (see sketch). On the pipes, from each of the five tanks, has been installed a Venturi meter rate controller such as is used in filtration plants. The assembled controller is here sketched. It consists essentially of a Venturi controller tube, vertical float pipes and registering device with control pilot valve.

The Venturi controller tube has 8-in. diameter inlet and discharge and 4-in. diameter throat, with the usual annular pressure chambers fitted with cleanout holes and vent cleaners. The float tubes are 12 in. in diameter and permit the use of 10-in. diameter floats which operate the register through cable connections. Into the top of these pipes a small stream of water is constantly flowing to set up a backward flow toward the meter tube and thus keep the small connecting pipes free from deposits.

A standard type-M Register-Indicator-Recorder, as manufactured by Builders Iron Foundry, is provided. The lower dial shows the momentary rate in gallons per 24 hours, the upper dial continually records this rate and the middle dial shows the total in gallons. Connected to the indicator dial main shaft, through suitable gearing and a cam, is a pilot valve which in turn is connected to and controls the position of the hydraulic valve in the controller tube. A rate adjusting knob is provided on the register.

Some Difficulties Encountered

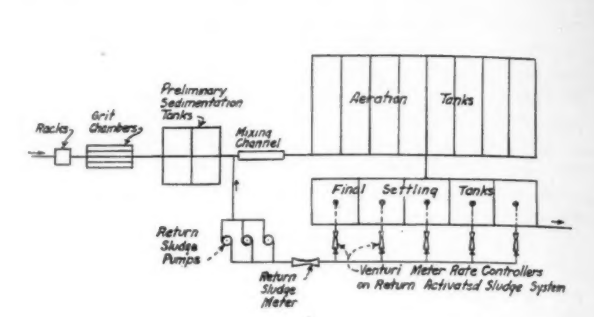

At the North Toronto plant the control is complicated by the fact that the header main into which the rate controllers discharge, is direct-connected to the return activated sludge pumping system. It is necessary to regulate the rate of sludge pumping so as to pump at a rate which will give the controllers some surplus to work on, but not to pump at so great a rate as to introduce a suction head which will empty the Venturi float pipes on the main activated sludge meter situated between the rate controllers and the pumps as indicated in the accompanying sketch of the plant arrangement.

Moreover it has been found in practice that with the rate controllers discharging into a common pipe and into a closed system the alteration of rate of flow passing through any one controller, by means of the rate adjusting knob, affects the rate through the others. Consequently, all must be readjusted in order to maintain a constant total rate of flow through the main return sludge meter between the controllers and the pumps. It would simplify the operation of the rate controllers if they were to discharge into an open channel leading to the pumps and the rate of pumping be governed independently by floats in a wet well.

At Morristown, N. J., an “electric eye” has been installed in the activated sludge final settling tanks. There are two air lifts for sludge withdrawal on each tank, one of which is manually operated to take care of the minimum sludge requirements. The other is operated through controls from the photo electric cell to maintain the sludge blanket at a predetermined level. It seems feasible to operate a sludge rate controller in conjunction with an “electric eye,” so as to automatically control the level of the sludge blanket in final settling tanks. This scheme would seem to be particularly advantageous in large plants with multiple units. However, even under such conditions, it would be desirable to discharge from the rate controllers into return sludge channels and not into a closed system.

The writer is indebted to Mr. Charles G. Richardson, Sales Engineer, Builders Iron Foundry, for the description of the rate controllers at the North Toronto plant. This plant is under the jurisdiction of Mr. R. C. Harris, Commissioner of Works, Toronto. The firms, Gore, Nasmith and Storrie of Toronto and Metcalf & Eddy of Boston are the consulting engineers.

Source Link: